With the strong advantages of highly intelligent system, quality effluent and cost efficiency on the mobile intelligent domestic wastewater treatment plant, Desun is positively following the central government's intention to build a new socialist countryside and making significant progress in the aspect of environmental protection and management.

The integrated wastewater treatment technology comprises biological treatment and membrane filtration. Thanks to the plug-and-play design, it becomes the most convenient and speedy solution.

Application

The treated effluent from the wastewater treatment plant equipping with moving bed biofilm reactor could be discharged to rivers or reused as landscape water.

1. Community with 100-1000 PE (population equivalent), especially for rural area.

2. Hotels

3. Marinas and golf courses

4. Workers’ rest area at construction site

5. Package manufacturing plants

6. Container wastewater treatment plants (emergency solution for humanitarian crisis)

Process flow diagram:

The A²/O process is applied with a semi-separated composition, which efficiently reduces fouling, maintaining stable operation.

Wastewater treatment process:

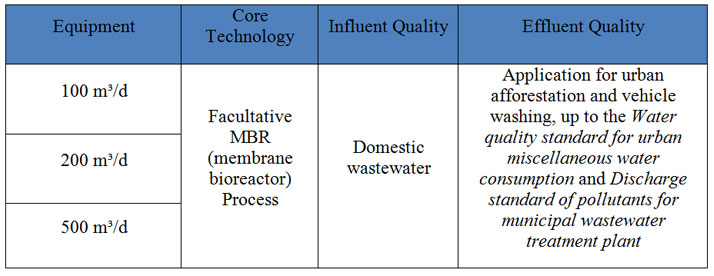

The membrane bioreactor process is designed as the core technology of the system, combining the technology of hydrolysis acidification which brings ring opening and releasing reaction. As a result, the process degrades part of the organic matter, improving the biodegradability of wastewater, creating better oxidizing reaction. The biochemical treatment is mainly applied in the process.

After the oil removal process for wastewater from dining industry, domestic wastewater is conveyed to the wastewater station by the piping system and runs through the grids. Wastewater that enters the equalization tank will be processed to maintain desired flow rate as well as to make mixture homogeneous. The pumping system helps to transfer the processed wastewater from the equalization tank to the equipment for biochemical treatment.

Hydrolysis acidification reaction comprises two stages: hydrolysis, during which partial solids and macromolecules are respectively degraded to soluble organic matter and small organic molecules, and acidification, which degrades carbohydrate to organic fatty acid. Meanwhile, the amount of excess sludge is decreased due to the anoxic process which reduces a large amount of organic sludge. The process partially removes COD, BOD and SS from wastewater and increases the biodegradability of organic pollutants, creating a superior reaction condition.

The hydrolysis acidification reaction taken before the anaerobic reaction can avoid methanogenesis with minimum requirement of environment and management. The realization of the process can be carried out easily. A small amount of COD has been processed during hydrolysis acidification, and aerobic reaction will be applied to reduce COD and other organic pollutants entirely.

Subsequently, wastewater will be processed with aerobic treatment, during which the aerobic biofilms are produced on the carrier. The organic matter is absorbed and decomposed by microorganism. At the same time, polyphosphate-accumulating organisms facilitate the removal of large amounts of phosphorus, ammoniacal nitrogen effects nitration with the help of nitrifying bacteria, and the membrane separates sludge from the wastewater. On one hand, the membrane increases the concentration of the activated sludge by separating the microorganism in the reactor, speeding up the biochemical reaction of the processed wastewater. On the other hand, quality and clear effluent can be produced due to the high filtration efficiency of the membrane.

Based upon the above processes, the water treatment station can produce demanded effluent for urban afforestation.

The Mobile Domestic Wastewater Treatment Plant has the following characteristics:

(1)Reusable effluent: stable operation without further process

(2)Simple process: no solid-liquid separation unit is needed due to the high separation efficiency of the membrane.

(3)Small footprint: high concentration of biomass can be maintained with the increase of the volume load; the duration time of wastewater in the process tank is shortened due to the high separation efficiency of the membrane.

(4)Less organic disposal: only 30% of sludge from the traditional process will be produced, thus resulting in low cost of sludge treatment. Only two sludge treatments are needed annually, if the wastewater is delivered by closed pipelines.

(5)The process filtrates bacteria and viruses to reduce the cost of dosing system, extending the application range.

(6)Strong impact resistance and broad application

(7)Automatic and well-equipped equipment

(8)Modular design: high flexibility helps to increase investment flows.

(9)Integration of the advantages of domestic equipment and German advanced technology results in a stable and reliable performance, as a pilot project.

(10)Nanocarriers: the process efficiency increased 10% compared to microorganism carriers

(11)Versatility—environment protection + internet + big data: on the basis of the user requirements, the plant can be operated through mobile phones with internet access anytime, anywhere. Equipping with remote operation, the system can be manipulated before the maintainer arrives.

(12)Cost efficiency: management by digital system with internet access effects low labor investment and high operation efficiency.

(13)Flexibility: with the features of small footprint and mobility, the process can be applied in various working conditions for wastewater treatment.